Is Your Jobsite Storage Secure? What The Pros Often Overlook

A heavy-duty lock feels safe. Real-world thefts say otherwise.

Contractors and facility managers often assume their containers are secure, until a break-in proves otherwise and equipment goes missing. Lawsuits for negligence have been filed against storage providers for failing to fix broken locks or install security cameras. Losses can reach tens of thousands, along with serious project delays and reputational harm.

Organized theft crews don’t guess. They find weak spots fast and then they strike.

The result? A false sense of safety and security that leads to downtime, liability, and preventable costs.

According to Overhaul, nearly 30% of reported cargo thefts with a known location occurred at facilities such as yards, terminals, or job sites.

If you rely on on-site containers, it’s time to evaluate your jobsite storage and find out if it is truly secure, or just looks that way.

FAQ: What’s the most common vulnerability in unsecured containers? The most common vulnerabilities are weak locks, a lack of surveillance, and inadequate access controls. Simple padlocks are easily defeated with bolt cutters, and containers without reinforced doors or lockboxes are prime targets for break-ins.

The Five Security Features That Actually Make a Difference on Site

Security is more than just a lock. When it comes to secure jobsite storage, the difference between a standard container and a secure one often comes down to five key features:

Security is more than just a lock. When it comes to secure jobsite storage, the difference between a standard container and a secure one often comes down to five key features:

- door type

- wall gauge

- vent construction

- lighting

- lock options

Each element plays a distinct role in protecting the contents of your jobsite from unauthorized access. From the outside, these containers may look like simple enclosures—but inside, they’re designed to function like a portable vault: durable, weatherproof, and built to stand up to real jobsite demands.

Jobsite boxes and cabinets offer some safety and protection, but without reinforced doors or accessories like lockboxes, lighting, or internal shelving, they fall short when real security is needed.

Secure jobsite containers use reinforced doors with multi-point locking systems that resist forced entry. Tamper-proof vents prevent unauthorized access while maintaining airflow. Motion-activated LED lighting provides visibility and deters intruders, especially at night. Lockboxes protect padlocks against bolt cutters, and digital or coded locks offer greater control over who enters and when. These features work in harmony to provide absolute security, not just the illusion of it.

Understanding the Risk Profile of Your Jobsite or Facility

Not every location carries the same risk. High-value sites, especially those near major highways, ports, or densely populated urban areas, are prime targets. According to Overhaul, the Southern California megaregion (due to its proximity to distribution hubs), accounts for roughly one‑third of U.S. cargo‑theft incidents. This is a reminder that location matters.

Construction sites are especially vulnerable. Safety isn’t just about PPE and signage; it also includes securing the tools and equipment your crew depends on to do the job right. Open layouts, minimal overnight supervision, and expensive materials left outdoors create easy targets for theft. Without proper surveillance, monitoring and lighting, thieves can act quickly, often undetected.

Understanding these environmental factors allows you to assess your portable storage needs and choose the right level of secure jobsite storage. By matching your container’s security features to the environment, you can avoid costly surprises down the line.

FAQ: What factors increase the risk of container break-ins? High-risk factors include proximity to major logistics hubs, lack of surveillance, poor lighting, multiple unsecured access points, and storage of high-value or easily resold materials.

Stories from the Field: When Storage Security Saved the Day

News of rising thefts and organized break-ins continues to surface across the industry, reminding teams to stay proactive about storage security. Upgrading to secure jobsite storage does more than offer peace of mind; security upgrades protect assets and keep projects on track. While Knaack-style boxes are common for small-scale tool storage, they’re not designed for large-scale transport or long-term jobsite security.

A contractor in Houston avoided $15,000 in tool losses after upgrading to a container with a tamper-resistant lockbox and reinforced doors. An attempted break-in failed, saving both time and money. Another jobsite manager shared that their secure container remained untouched over a long weekend when nearby sites suffered multiple thefts.

Upgraded containers provide a higher level of durable protection and usability.These stories demonstrate how even a small investment in upgraded security features can pay off significantly when it counts most.

Why Schools, Hospitals, and Cities Rely on Secure Jobsite Storage

Secure jobsite storage isn’t just for construction professionals. School districts use them to store tech equipment, band gear, and maintenance tools. Hospitals rely on them for organization of emergency supplies, medical overflow, and facility upgrades. Municipalities store things like road salt, voting machines and storm recovery gear. School maintenance shops, city service yards, and emergency facilities all rely on secure storage to keep operations running smoothly and compliantly. Many also rely on labeled bins or internal shelving systems to keep gear organized and easy to access, especially when multiple teams share a single container.

The common thread? These organizations face accountability, regulation, and high-stakes consequences if something goes wrong. They have a responsibility to safeguard the rights of the people they serve. Their decision to use secure storage reinforces the value of proactive planning and builds trust with the communities they serve.

Secure Storage Doesn’t Mean Complicated: Setup and Access Made Simple

One common myth about secure jobsite storage is that it slows things down. In reality, today’s secure containers are designed to be user-friendly and durable. They’re built for jobsite efficiency.

Delivery can be scheduled around active site operations, and storage containers can be dropped into tight areas with minimal disruption. Features like accessible cargo doors, internal man doors and interior lighting streamline daily use.

Many teams prefer secure jobsite storage for the convenience alone. It helps them stay organized, focused, and on track during the busiest phases of the project.

FAQ: Can I add a secure container to a tight or active jobsite? Yes. Containers can be delivered and positioned with minimal disruption, and features like personnel doors or cargo access make them practical for high-traffic environments.

The True Cost of Insecurity: What Theft and Downtime Really Cost a Jobsite

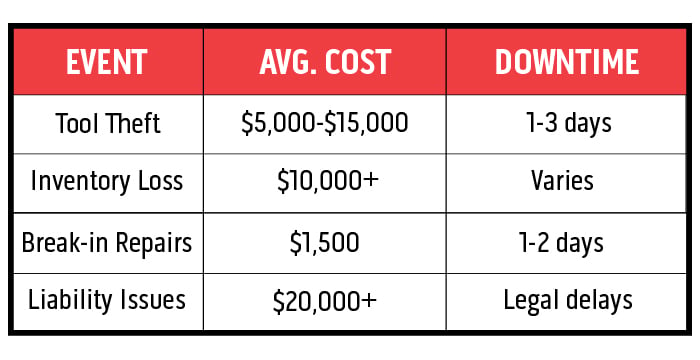

Jobsite theft is more than just the cost of stolen goods. Tool losses alone can run $5,000 to $15,000. Inventory theft can exceed $10,000. Even a minor break-in may cost $1,500 in damage and delay work by a day or two. For small teams, those setbacks can seriously affect timelines and budgets.

If you add soft costs like insurance hikes, project delays, employee stress, and damaged customer trust, the total cost of insecurity becomes much higher. In some cases, legal liabilities for negligence have reached tens of thousands of dollars.

Secure jobsite storage helps prevent these losses before they happen by protecting what matters most and keeping your team on track.

Protect Your Site with the Right Secure Jobsite Storage

Your project and your team deserve more than a standard lock, they need dependable storage management. Now is the time to evaluate your jobsite’s risks, identify vulnerabilities, and choose a solution designed for protection.

A secure jobsite storage container is more than a rental; it’s peace of mind, fewer delays, and fewer losses. That means theft prevention and minimum downtime for your project schedule. Don't be afraid to ask questions.

You’ll find the SiteBox logo on portable storage containers trusted by contractors, schools, and municipalities across the Midwest and the Carolinas because secure jobsite storage should stand out for the right reasons. Ready to take the next step? Get a tailored quote, explore security products, and let us help you choose a jobsite storage container that matches your site’s needs.

Protect your tools, your timeline, and your bottom line. Request your jobsite security consultation today.